Next-Gen Composite Solutions for Multi-Domain Missile Defense Systems

Mobilizing domestic manufacturing with carbon fiber composite materials.

Materials that Strengthen National Security

Toray is a global leader in advanced materials, delivering the most technologically sophisticated and cost-effective solutions at scale. Together with a heritage of proven aerospace success, our composite materials are integral to critical defense and missile systems.

Our domestically sourced composite material offers a wide range of carbon fiber, thermoset, and thermoplastic prepregs, as well as complementary products integral to mass-produced satellite constellations, hypersonic vehicles, radomes, swarms of high-flying pseudodrones, and more.

Revolutionizing U.S. Defense

The Golden Dome of America program is a multi-layered defense shield designed to protect the American homeland and deter external threats with unwavering precision, ensuring National security and resilience from ground to space. As a trusted partner to the defense sector, Toray delivers material solutions that enhance mission-critical systems.

Our Proven Solutions for U.S. Defense

Toray offers an extensive range of carbon fiber, thermoset prepreg systems, and thermoplastic composite solutions to support every stage of development from prototyping to high-volume manufacturing.

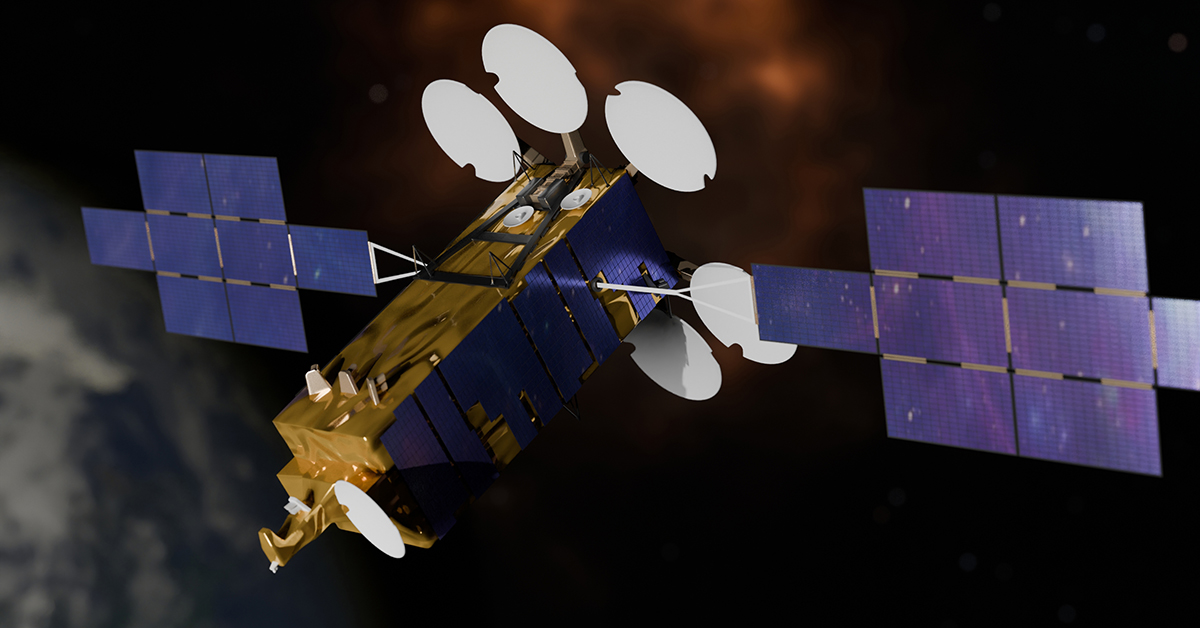

SPACE & SATELLITE

Applications range from lunar rovers, heat shields, bus structure, solar arrays, reflectors utilizing high modulus pitch and PAN-based fibers and fabrics.

Key supplier to next-generation ‘New Space’ launch vehicle programs, which utilize Toray’s advanced composites out-of-autoclave materials for a variety of launch structure applications.

LAUNCH & MISSILE

These thermally stable materials replace traditional titanium and other metals, offering increased design flexibility and significant weight savings.

Toray’s high temperature product suite of Cyanate ester, polyimides, and BMI solutions is tailored for advanced structural, ablative, operating in excess of 260-370°C (500-700°F), and ceramic matrix and carbon-carbon precursor applications, operating in excess of 2,250°C (>4,000°F).

RADOME & ANTENNA SYSTEMS

Ideal radome materials are both electrically pure and low loss, meaning they are truly transparent to electronic signals.

Toray’s radome materials are produced in carbon-free isolated facilities, ensuring the lowest risk, highest performing electrically pure products for military and satcom radomes. We have the largest Df/Dk database from 10-60 GHz to support your needs.

AEROSPACE, HELICOPTER, UAV

Toray material solutions are qualified on major aircraft programs for applications ranging from leading edges, rudders, and vertical & horizontal stabilizers, propulsion blades, and beyond.

Our advanced material solutions are valued for helicopter structural assemblies, weight savings in military jet engines, and low-cost out-of-autoclave/vacuum-bag-only processing for ultra-strong and light UAV solutions.

your strategic advantage starts here.

Creating Value with Toray

This next-gen national defense program demands a strategic advanced composites partner with:

-

A well-established national supply network

-

A fully integrated, scalable, and agile value chain

-

The largest domestic carbon fiber production capacity

-

Flexible manufacturing capabilities across North America

-

Facilities meet U.S. security clearance and FOCI standards

-

A proven track record in aerospace and defense applications